| Availability: | |

|---|---|

C10100 C10200 C12200 C12000 C11000 C44300 C70600

Copper tubes are a popular choice in various industries due to their excellent thermal and electrical conductivity, corrosion resistance, and malleability.

Production Process:

Copper tubes are typically produced through a process called extrusion, where a billet of copper is forced through a die to create the desired shape and size. The tubes can then undergo various surface treatments, such as annealing or plating, to enhance their properties and appearance.

Standard Sizes:

Copper tubes come in a wide range of standard sizes, with common diameters ranging from 1/8 inch to 8 inches, and wall thicknesses varying from 1/16 inch to 1/2 inch. These standard sizes make copper tubes versatile and suitable for various applications.

Applications:

Copper tubes are widely used in industries such as plumbing, HVAC, refrigeration, and electrical. They are commonly used for transporting water, gas, and refrigerants, as well as for heat exchangers, electrical wiring, and medical gas systems. With their excellent conductivity and versatility, copper tubes offer a reliable and durable solution for a wide range of engineering and design needs.

Specification

Product Name | Copper Pipe |

Application | Air Condition Or Refrigerator |

Specification | 3-16 |

Material | T1,T2,C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,TP1,TP2,C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,TU1,TU2,etc |

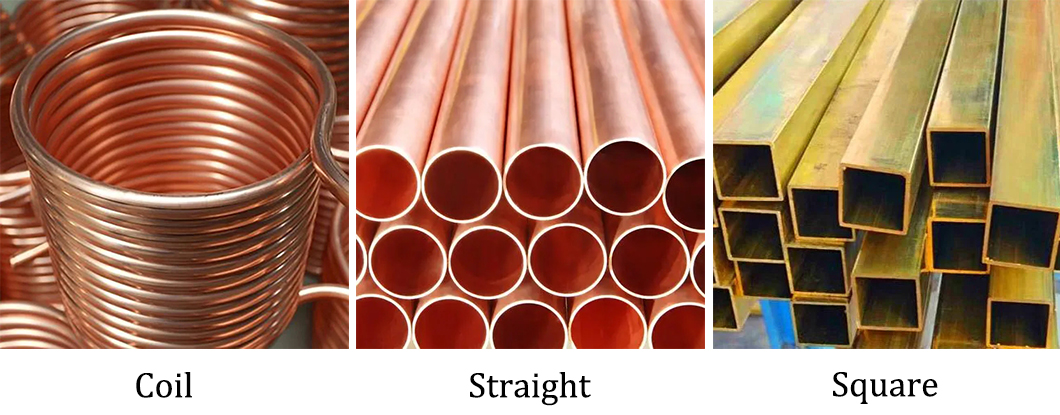

Shape | Round, square, rectangular, etc. |

Length | 3m,5.8m, 6m, 11.8m, 12m, or as required. |

Cu (Min) | 99% |

Surface | Mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required. |

Alloy Or Not | Non-Alloy |

Ultimate Strength (≥ MPa) | 460-680 |

Elongation (≥ %) | 1 |

Wall Thickness | 0.2mm-120mm |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,etc |

Outside Diameter | 3/16-7/8 |

Model Number | COIL |

Place of Origin | China |

Package | Standard Seaworth Packing |

Sample | Sample Freely |

Application | Construction , Building,Decoration , Curtain Wall , Roofing, Mould , etc |

Product Advance

Copper tubes offer several advantages that make them a popular choice in various industries:

1. Excellent Thermal Conductivity: Copper is known for its high thermal conductivity, allowing for efficient heat transfer in applications such as HVAC systems, heat exchangers, and refrigeration units.

2. Superior Corrosion Resistance: Copper has natural anti-corrosive properties, making copper tubes highly resistant to rust and corrosion. This ensures longevity and durability in harsh environments.

3. Malleability and Formability: Copper is a highly malleable and ductile material, allowing for easy shaping and forming of tubes to suit specific design requirements.

4. Longevity and Reliability: Copper is a durable material that resists degradation over time, offering long-term reliability in various applications. Copper tubes are known for their longevity and low maintenance requirements.

5. Environmental Friendliness: Copper is a sustainable material that is 100% recyclable without losing its properties. Using copper tubes in your projects can contribute to environmental sustainability and reduce the carbon footprint.

6. Antibacterial Properties: Copper has natural antibacterial properties that help inhibit the growth of harmful bacteria, making copper tubes a hygienic choice for applications such as plumbing and medical gas systems.

Product Application

Some common applications of copper tubes include:

1. Plumbing and Heating Systems: Copper tubes are widely used in plumbing systems for transporting water, as well as in heating systems for radiant heating, underfloor heating, and hot water circulation.

2. HVAC Systems: Copper tubes are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems for refrigerant lines, heat exchangers, and condenser coils due to their excellent thermal conductivity and corrosion resistance.

3. Refrigeration and Air Conditioning: Copper tubes are ideal for refrigeration and air conditioning systems due to their ability to efficiently transfer heat, making them essential components in refrigerant lines and evaporator coils.

4. Medical Gas Systems: Copper tubes are used in medical gas systems to transport gases such as oxygen, nitrogen, and compressed air in hospitals, clinics, and medical facilities due to their cleanliness and antibacterial properties.

5. Automotive Industry: Copper tubes are used in the automotive industry for various applications, including fuel lines, brake lines, and air conditioning systems, due to their durability, corrosion resistance, and thermal conductivity.

6. Industrial Applications: Copper tubes are used in various industrial applications such as heat exchangers, boilers, steam lines, and process piping due to their reliability, longevity, and ability to withstand high temperatures and pressure.

7. Electrical Applications: Copper tubes are also used in electrical applications for grounding systems, lightning protection, and electrical wiring due to their excellent conductivity and corrosion resistance.

Packing&Delivery

1. Packaging materials: We typically use high-strength cardboard boxes or wooden crates to package copper tubes to prevent damage during transportation. For internal cushioning, we use foam padding or foam sleeves to protect the copper tubes from vibration or impact during transit.

2. Labeling and tagging: We clearly label the packaging with product information, including specifications, quantity, weight, etc., to help customers quickly identify and verify the goods upon receipt.

3. Transportation method: We choose reliable logistics partners to ensure that copper tubes are delivered to customers in a safe and efficient manner. Depending on customer requirements and order quantity, we select the appropriate transportation method, including land transportation, sea transportation, or air transportation.

4. Quality inspection: During packaging and transportation, we conduct quality inspections on copper tubes to ensure that the products meet relevant standards and requirements.

FAQ:

Q1:Can you send samples?

A:Of course, we can provide customers with free samples and express shipping service to all over of the world.

Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Q5:What about product prices information?

A:Prices various according to periodic price changes of raw materials.

Q6.Do you provide custom made Products service?

A: Yes,if you have your own design , we can produce according to your specification and drawing.

Q7:What are the certifications for your products?

A:We have ISO 9001, MTC, third parties' inspections are all available such SGS, BV ect.

Q8:How long does your delivery time take?

A:In general, our delivery time is within 7 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q9: How many countries you already exported to?

A:We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana,somalia and other African countries.Our export experience is rich, we familiar with different market demands, can help customers avoid a lot of trouble.

Q10:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q11:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q12:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion and various climate changes during ocean transportation.